Iso-Flate® Inflatable Seals

The Iso-Flate® range of Inflatable Seals has been developed for (and in conjunction with) some of the most prestigious OEM’s in Pharmaceutical containment/process equipment. Manufactured in the UK, the seals are subject to strict testing, quality control and traceability functions, in order to satisfy the industries need for a clean, safe and functional solution to hermetic sealing.

Features and Benefits

- Precision Spark Eroded Vulcanisation tooling, and strict extrusion tolerance ensures highest quality of vulcanisation

- Over 100 profiles available in FDA silicone, Anti-Microbial Silicone, FDA EPDM, FKM and many other materials

- Precision moulded rubber valves, and machined steel valves to suit vast range of housings adhering to stringent leak rates

- Unique seal identification number providing detailed traceability for each individual seal supplied

- Rapid cycle fatigue testing available providing accurate, application specific cycle life estimates

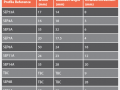

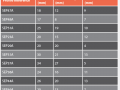

Profiles:

With over 100 extruded profiles available, and multi material compression vulcanising tools, we are able to offer a vast combination of shapes/materials to suit your application.

Materials:

Iso-Flate® inflatable seals are predominately stocked in FDA compliant silicone and EPDM, but are also available in Anti-microbial silicone (Bio-Flate) – Click the logo to launch the specification sheet for this ground breaking material, Fluoroelastomer , and many other compounds should the application demand it. We can in most cases provide seals in any colour to accommodate clients corporate branding needs.

Due to the demands from Industry regarding Atex regulations for combustible powders, Sealing Projex have developed materials that are Anti-static and even conductive in surface resistance value. If you require an anti-static Inflatable seal for your application please feel free to contact us for further information.

Inflatable seal profile configurations:

Extruded Inflatable seals can be joined either endless into a loop, have straight lengths with vulcanised ends “See image – ” or manufactured with mitred or moulded radial corners. The most popular configuration is to be manufactured into an endless ring and used in the configurations shown in the diagram below.

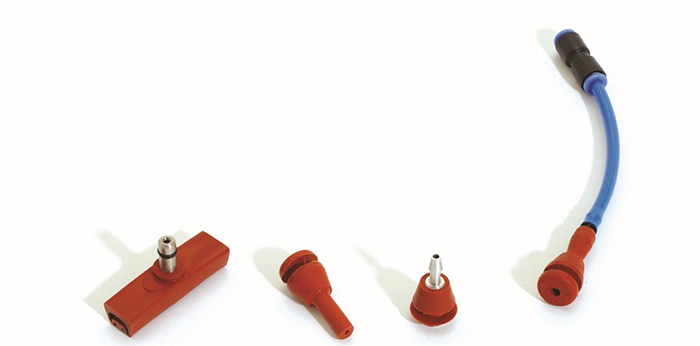

Valve Styles:

In addition to our standard rubber push-in valves and pneumatic tube fittings, we also have the ability to machine custom steel fittings with precision. We currently have 40 different Valve connection configurations in the Iso-flate range so the possibilities are endless. For technical information and support please contact us.

Iso-Flate® Containment sealing solutions brochure

Please click on the brochure image to view or download our containment sealing brochure

Drum Sealing Vacuum Membranes

Please take a look at our new 3D animation for our Drum Sealing Vacuum Membranes

This could be of interest for future drum Sealing applications where conventional extruded Inflatable seals don’t have enough travel.